St. Clair County ResidenceBuilding Automation

In 2014 Johnson Heating and Cooling L.L.C. was contracted to install a building automation system that would control the mechanical systems for a high-end home, located in St. Clair County, Michigan.

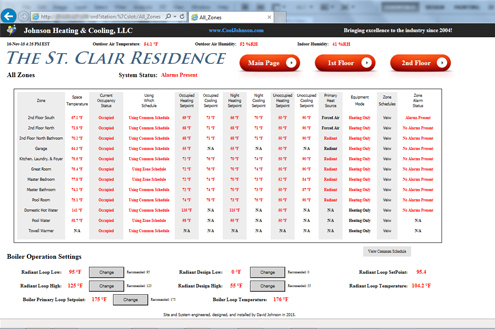

BAS Page“It’s sometimes a curious thing how with many possessions comes much trouble. Solomon (in the Holy Bible), and Clyde, my old friend and neighbor, have said similar things. Our work at the residence in St. Clair County was done for several reasons, one of which was to take systems which had something like 20 thermostats and combine them all into one system, wherein the settings and systems as a whole could be controlled, tested, alarmed, and monitored. Perhaps our biggest purpose was to reduce the “trouble” caused by the many systems, components, and devices. We didn’t design or install the original HVAC and mechanical systems, but rather we were hired to remedy many of the deficiencies in the work of others, and to simplify and unify what they had done.

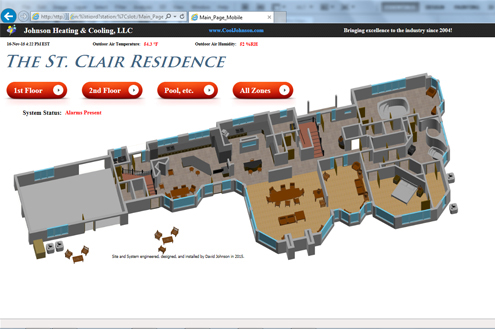

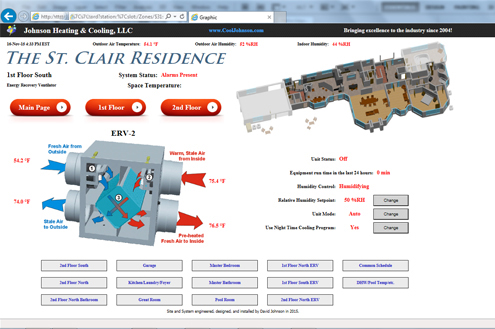

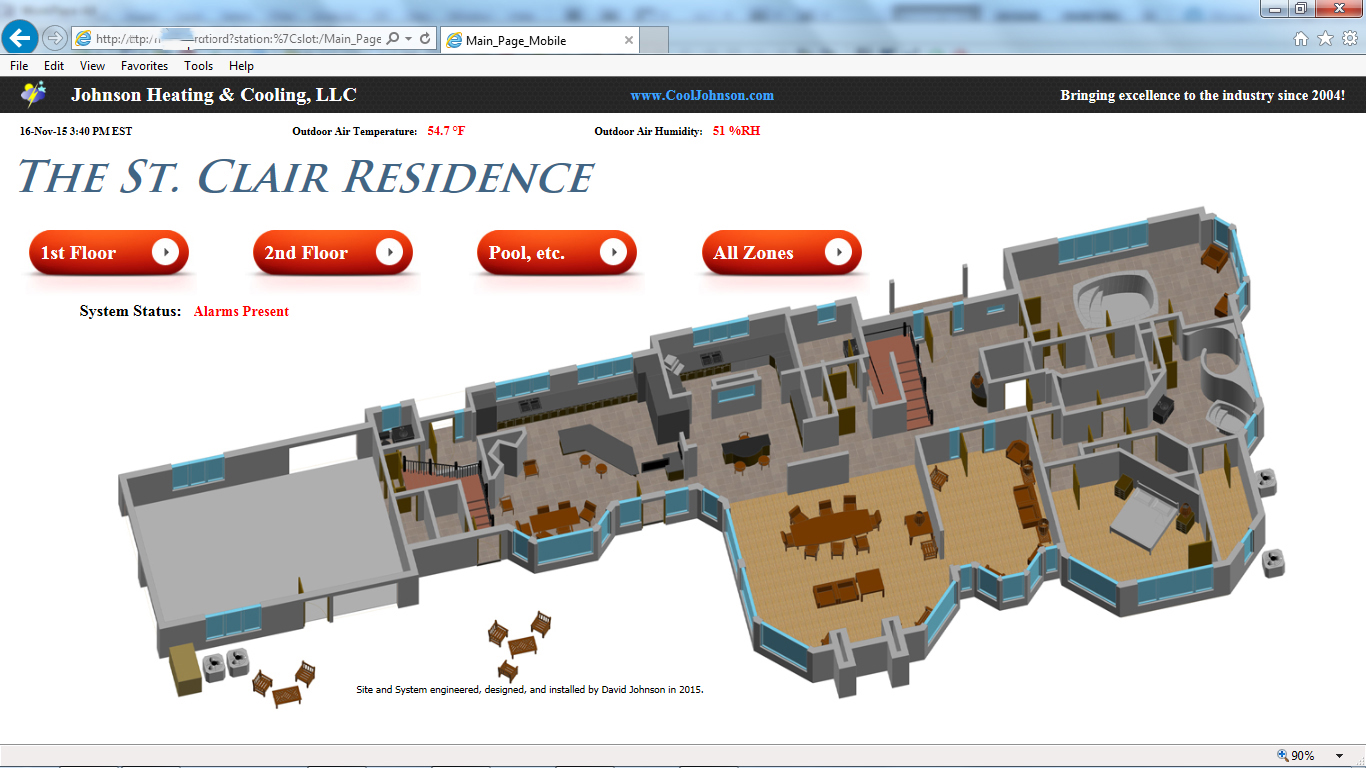

As I’m sure that you can tell by looking at the pictures, the graphics are second to none. We went above and beyond and actually included graphics which represent the actual furniture in and around the home. The 3-D model which we created is actually to scale within something like 6” from end to end, and we produced the drawing using actual industry standard AutoDesk, AutoCad software, so the plans can be used for any future work done at the location. The idea is that we want the system to accurately represent the facility’s layout so that it is easy to operate. We redrew the entire building ourselves & did not get any computer files from the owner or original architect, as the original plans were drawn free hand.

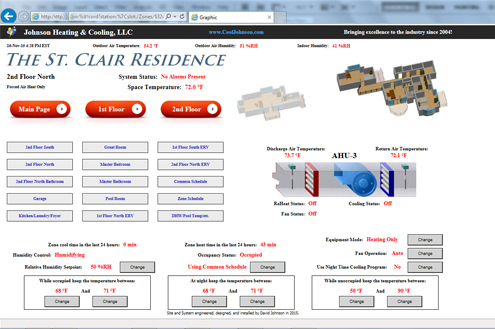

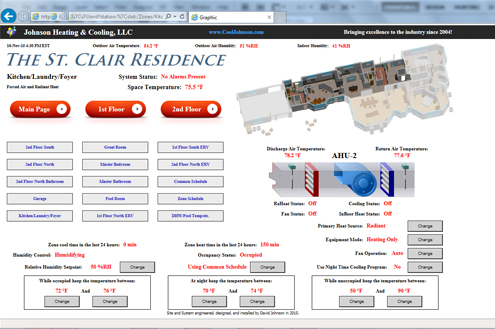

A cool feature of the system is that each of the zones pages shows the representation of the area serviced by the equipment by “lightening” the areas not serviced by the equipment, so that the area serviced stands out in the graphic. Preparing the graphics in this way is very time consuming, but then, because we are very fast at creating “top-end” graphics, it’s also affordable.

In terms of the work involved, it was pretty “cut and dry”, however it was difficult and time consuming. Most of our work was done in a crawl space, and working at a residence is much different than working at a non-residential facility. For the size of the building, one would be surprised by the condition and amount of mechanical systems on-site. The zones for cooling and heating overlapped, wherein the air conditioning (or cooling system) serviced multiple zones which heat, and every cooling and heating zone had it’s own thermostat. In some areas a heating thermostat would be only inches away for a cooling thermostat, and in other areas there would be only a heating or cooling thermostat, which was not labeled. The previous means of control left much to be desired, and tuning the equipment and writing the code would prove to be problematic and difficult regardless of how the matter was handled.

Additionally, the walls are masonry and steel and the in-floor heating system would transfer heat energy to the wall’s steel and masonry more readily than it does to the air via convection, which caused significantly more trouble than one would expect, as the wall modules always seem to read higher temperatures. The wall construction is unusual in that the steel backing is behind the masonry face (something like stucco) of the wall, so that the steel backing is hidden. This construction technique was unusual and also caused problems in terms of mounting wall modules and running new wires.

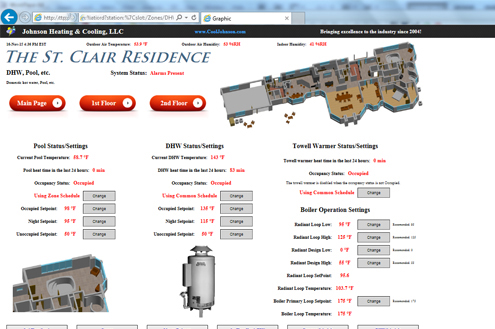

In the end we programmed the system such that it would be as simple to operate as we could make it. Originally, the boilers always ran at a temperature of something like 180 degrees, however, we wrote code which only activates the boilers when needed, with an outdoor air temperature reset, and with a demand to set point reset. Also, the previous system did not make provision for night time setback and the like, so we included that into the graphical user interface and code as well. The server which we used was the same server used in the Oakland Mall building automation project, and like the Oakland Mall building automation project, we needed to make custom components for this automation system as well.

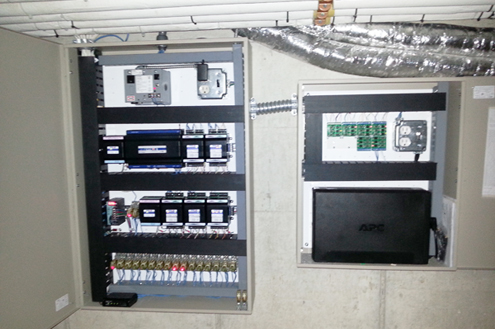

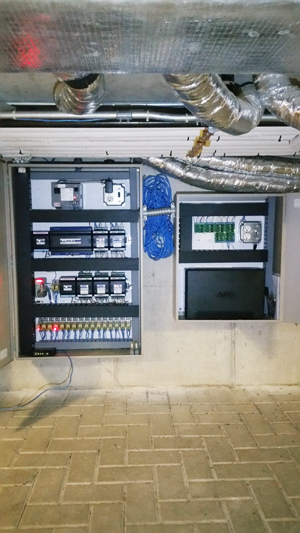

Of note; because the owner was meticulous with her home and it’s decorating, we offered several options to be used for the wall modules. The owner expressed a desire to have small “mirror style” wall modules. We cut custom mirror plates with our CNC machine out of high quality acrylic, build PCB’s for behind the mirror plates, and the built, and painted matching backers for the wall module with our 3D printer. We used our own wall modules for two reasons. Firstly, and most importantly, the customer preferred the look of our wall modules more than the look of the “off the shelf” wall modules which are on the market. Since the customer liked our wall modules better, that is what we provided. Additionally, and also of importance, is the fact that we were able to cut some costs and increase quality by using our own wall modules. Humidity sensors for the HVAC industry are quite expensive, and the items in widespread use in the HVAC industry seem to be years behind in their development as to what may be purchased on the component level, like for instance from places that sell electronics components, like Mouser. We were able to offer increased quality at a lower price. As with many other sensors, like CO2, CO, etc, humidity sensors wear out over time, so it is very notable when a more robust/recent sensor design may be used, because it equates to a tangible benefit in the not too distant future. Because the I/O in the Honeywell Modules was not able to read the output from our humidity sensors, we build signal conditioning PCB’s and inconspicuously placed the boards in the controls cabinet so that the values could be read. We had already designed the boards for another project, so the signal conditioning boards were also very inexpensive and allowed for the highest quality humidity sensor to be used.

Because the structure of the system required that we have a disproportionately larger number of Digital outputs and a disproportionately small number of analog outputs, and since the I/O modules used on the project contain four digital outputs and four analog outputs, we decided to turn our analog outputs into digital outputs by using an analog to triac output (digital output) conversion board. The end result is that we were able to effectively double the number of digital outputs in the system by using extra analog outputs, and that at a very low cost per output. We were able to avoid purchasing an additional $2,500 or so in materials, simply by using a little ingenuity and market sense. Of course we needed to build a base plate for mounting the analog to digital conversion boards, since they are not typically mounted in such a way, however after a couple of hours of human work, and after a couple of hours of the 3D printers work, we had produced an excellent method for turning analog outputs into digital outputs, and doing so in a sharp and aesthetically pleasing way.

Another interesting feature of this system is that we made provision for night time and away schedules for domestic hot water tanks and the indoor swimming pool. Since the owner probably doesn’t use much hot water when away or during strange times, like at 1:00 am, we gave them the ability to set a schedule for which time the hot water tanks and swimming pool should be at which temperature. This isn’t a huge benefit, but if used correctly, it’s a benefit none the less.

One major concern of the owner was that the system should provide for alarming in the event of a power outage. Such as this was important to the customer, we installed a battery back up in the system so that the customer would receive an alert in the event that the power should fail. In the event that the power does fail, the customer would have something like a day or two, of the ability to log into the system, because the battery backup would keep the server on line, and also because the battery backup in the modem would keep the modem on-line.