St. Joseph Mercy Oakland U. C.Building Automation

In 2013 Johnson Heating and Cooling L.L.C. was contracted to install a new building automation system in a St. Joseph Mercy Oakland urgent care facility. The men at Johnson Heating and Cooling, LLC "pulled a rabbit out of a hat" and completed the project ahead of schedule and with the quality and sophistication that our competition could only dream of.

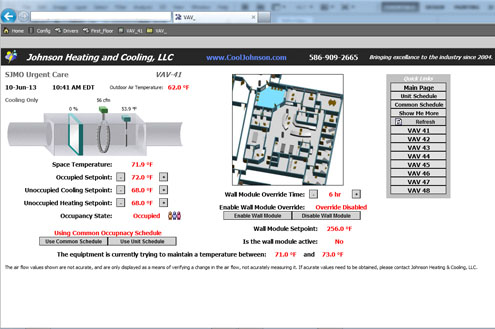

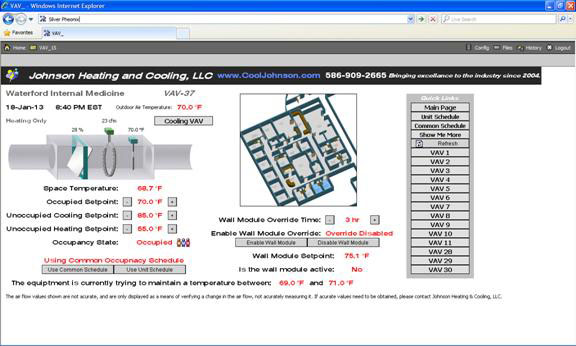

BAS PageWho said Rome wasn't built in a day? The St. Joseph Mercy Oakland project was a bit of a rush job to say the least. With only two weeks to have the building automation system designed, installed, programmed, and functioning properly, Johnson Heating and Cooling, LLC showed that they can get the job done in time and get it done well without inconveniencing the plans of our customers. The building automation system that Johnson Heating and Cooling, LLC installed has an extremely complex, yet efficient program that controls the VAV boxes, and the heating, ventilation, and air conditioning equipment on the roof of the building. The building automation system features a three-dimensional graphical user interface, optimized and reactive equipment control (based on demand), fully programmable temporary occupant overrides, a 16 page user manual, energy efficientcy tuning, advanced mobile compatibility features, and is accessible via the world wide web without the use of any proprietary software.

The concept behind the heating, ventilation, and air conditioning (HVAC) equipment control, in the control program, was too ramp up the HVAC equipment output as the temperatures of the "most off" zones became further from their set points. For example, and this is a very simple explanation of the code, as the coldest zone became colder, the roof-top unit on the roof would produce more hot air. Because cycling HVAC equipment is inefficient and shortens the life-span of the equipment and controls, the idea is to reach an equilibrium, where the units on the roof would run, but at a rate of say, 41%, rather than cycle on and off again. Johnson Heating and Cooling, LLC accomplished this end by controlling each units' fan output via a variable frequency drive in each unit, as well as controlling the units' conditions via the control system.

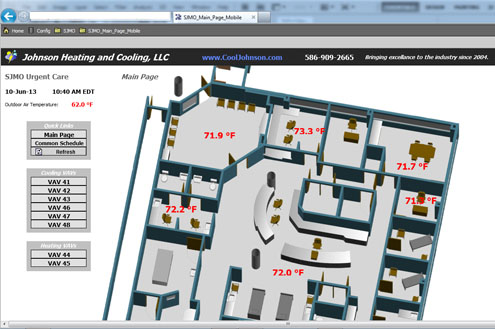

Three-dimensional graphics of the facility where made, and are to scale plus or minus about 3%. Desks, chairs, tables, toilets, sinks, computers, columns, and even examination beds where included in the graphics. The color of the walls in the graphic was even set to match what was in the facility (mostly an aqua-blue color). The three dimensional graphical user interface for the building automation system displays the temperatures of the facility at the point of their source, the wall modules. The temperatures for each VAV zone are interactive links to the respective temperature's VAV controller, so if a person using the building automation system wishes to view a certain zone's VAV or change the settings associated with that zone, all he need do is click on the temperature displayed for that zone. All of the dynamic values displayed change in real time, and change without having to refresh the page. Unlike many building automation systems, this system is designed to be used by the "lay-man" and is not made to be used only by very experienced controls contractors. The functionality of the user interface side of the building automation system performs much like a generic programmable thermostat.

On this project, unfortunately, the HVAC equipment will not realize as much of an energy savings as it could. To date, the customer has not contracted us to integrate the exhaust fans into the building automation system, so the equipment must provide outdoor air 100% of the time until the exhaust fans are integrated. Once the exhaust fans are integrated, the other HVAC equipment will be programmed to shut down when not needed for space conditioning and when the exhaust fans are off. Currently, the HVAC equipment must provide fresh air to the structure while the exhaust fans are on.

Seamless equipment operation and easy adjustment are just a few of the many great qualities in this building automation system. Typical programming language can be very difficult for even the most experienced controls contractors, but we make our code easy to read and use. After a couple of years or even months even the original author has difficulties working on code that he has written, so we try to make things as easy and organized as we can. Certain program "handles" are put into the code so that if adjustments need to be made to the way the program operates, we don't have to dig too deep into the code. As with all of our building automation systems, this project was tuned and examined for a period of a few months to ensure that the heating, ventilation, and air conditioning equipment functioned properly and efficiently.