Waterford Internal Medicine Building Automation

In 2012 Johnson Heating and Cooling L.L.C. was contracted to engineer, program, and install a building automation system in a facility operated by Waterford Internal Medicine.

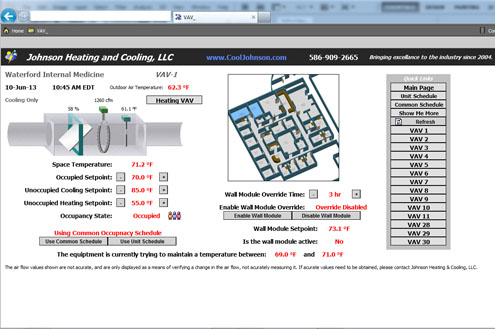

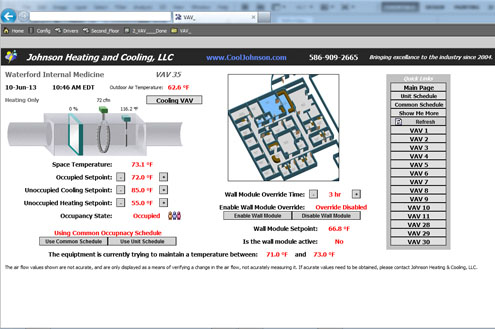

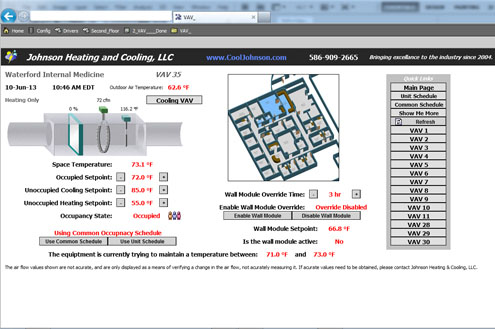

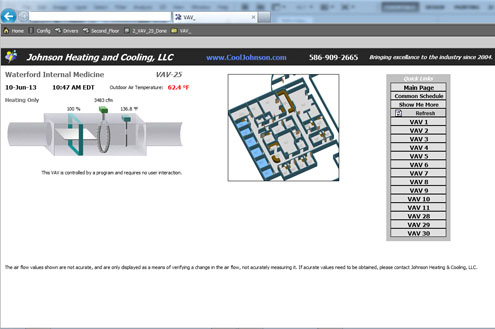

BAS Page"Personally, I think that wall modules without digital displays cause building automation systems to be hated by the people that have them in their buildings", David Johnson. Imagine wanting to turn the temperature set point for your area down, but not actually knowing what you were setting the set point to. If the controls contractor simply told you, "just turn this lever to the left if you are hot, and too the right if you are cold", wouldn't that frustrate you? In 2012, Johnson Heating and Cooling, LLC installed a building automation system in a facility operated by Waterford Internal Medicine, which features Honeywell's T-7560A Digital wall modules that display both set point temperature and space temperature, a 22" touch screen display (which was mounted in the hallway) to access the building automation system, and configured the system to be accessible and programmable from any computer or smart device, via the world wide web. The new system is as accessible and transparent as any building automation system can be, while still being cost effective.

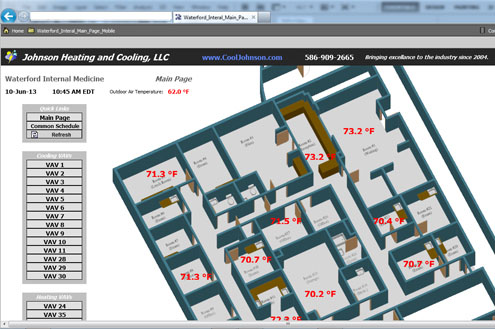

Johnson Heating and Cooling, LLC began the project by mapping out the current control system in the facility and comparing our findings with what the township had on file for the building. Three dimensional building and mechanical plans where made, and inefficiencies in the old design where dealt with by adding variable air volume (VAV) boxes to the parts of the facility that had heating, ventilation, or air conditioning problems. Before beginning the job, we programmed the controllers, drew new mechanical plans, obtained materials, and made wire diagrams. Most of our installation work was completed on the weekends or after hours because we did not want to disrupt the operations of the facility.

Optimized equipment control programs, equipment scheduling, temporary zoning override set points, modulating variable air volume box damper control, and optimized mobile device compatibility are just a few features of the control system installed at the facility. Both the variable air volume boxes and the HVAC equipment on the roof modulate output based on demand. The variable air volume boxes react to heat loads based on one tenth of a degree F, and the HVAC equipment on the roof does the same. The configuration of the new building automation system is a far cry from the previous system, which was not using a responsive modulation program to adjust roof-top equipment output. The end result is that the variable air volume boxes get the hot or cold air that they need to properly condition the areas that they serve, but there is never an excess of supply air.

Equipment scheduling is important for obvious reasons. It is wasteful to operate HVAC equipment when it is not needed. Often operators of building automation systems are worried about setting schedules to be unoccupied and having people who come into the facility after hours be uncomfortable. Even though the building automation systems that Johnson Heating and Cooling, LLC designs, engineers, programs, and installs are all made to be as user friendly and as accessible as they can be, the systems are still a little complicated to the average person who has never used that particular building automation system, so that is why we included temporary overrides. The temporary overrides are fully programmable and are easily enabled or disabled via the building automation system interface. To activate a temporary override, if it is enabled, all an occupant need do is set the temperature set point on the wall module to what they want the temperature to be. We programmed the server to watch the set point values on the wall modules, so that when one of the values change, the system will know that someone is uncomfortable. The building automation system will then begin a count down, for the time set in the building automation system interface, and will change the set point temperature to the value to match the value on the wall module that has had it's set point temperature changed. If the building automation system administrator wants to disable the override feature, all he need do is just click his mouse over the disable button, and then the server will ignore changes made to the wall module's set point temperature.

When an experienced controls contractor hears the term "morning warm-up", he thinks "poor programming" or "poor system". Morning warm-up is the term used to describe the control condition of equipment on a system that does not utilize a good, responsive control modulation algorithm. Typically a "morning warm-up" condition causes the equipment to operate at maximum output for a predetermined amount of time so that the structure could heat up or cool down quickly when it is switched to the occupied condition (as is usually done in the morning). At Johnson Heating and Cooling, LLC, we have never used morning warm-up's in our equipment control programs because they are wasteful and we always program our equipment control algorithms to be responsive according to zone needs. Morning "warm up's" typically put equipment into a certain condition (usually 100%) for a certain amount of time, while our programs always put equipment into a certain condition based on the need's of the zones and based on how far off the zones are from set point. If the zones temperatures are very much over set point, the modulation output of the air conditioning equipment will also increase proportionately (but also inversely, as in the discharge air temperature set point of the air conditioning equipment goes down and fan output goes up). The end result of our system is that every day a few dollars are saved in energy costs, and the zones in the building are always at set point

There is no room for improvement when it comes to the responsive equipment modulation control programmed into the system at Waterford Internal Medicine. As a zone's space temperature becomes off from the zone's set point temperature, the damper in the VAV modulates. The dampers are at rest when the zone is at set point, and will reach equilibrium based on the heat loss / gain of that zone. If a damper needs to be at 23% open for a zone to maintain exactly 71 degrees F, then that is where you can expect to find the damper when you look at it's value on the building automation system interface.