Cooling Water and Boiler Chemical Treatment

With over a decade of experience in water chemical treatment, the team at Johnson Heating and Cooling is ready, willing, and capable of saving you money on your chemical treatment program. Providing water treatment with chemicals is an industry and profession in and of itself. There are three reasons why water chemical treatment programs are used, and the first reason is safety. Untreated cooling water systems can be teaming with bacteria, like an untreated fish aquarium. Typically, a storage tank loaded with bacteria doesn't pose a serious health risk in and of itself, but when the water is shot into the air, as is done with an evaporative cooler, a.k.a. swamp cooler, the bacteria can become airborne, and at that point may be deadly. Legionnaires' disease is the main safety concern regarding swamp coolers.

The second reason why water treatment programs are used is to protect the equipment. Our chemical treatment programs always achieve very good corrosion prevention and scale reduction. Any one who has had their metallic items damaged by mother nature can imagine what is happening inside a hydronic system without a chemical treatment program. Some of the chemicals that we use prevent corrosion by adhering a thin protective layer of chemicals over the surfaces on the inside of the system, while others greatly reduce the ability of the water to react with the surfaces on the inside of the system. The chemical treatment program that is right for your equipment is determined on a case by case basis, and is dependant on several factors which change from customer to customer, and system to system. Whatever your system's chemical treatment needs are, you can be rest assured that we will address them properly and in a cost effective manor.

The third reason why chemical treatment programs are used is to improve and maintain high levels of system efficiency. In the HVAC industry, scale is seen as an insulator by the educated eye. Every heat exchanger, whether a section of a cast iron sectional boiler, or the tubes in a shell and tube heat exchanger, is more efficient if it transfers heat more readily. Adding insulation, by means of failing to address the cause of scale build up is simply put, mechanical negligence. Most hydronic systems have something called a pressure reducing valve, which automatically maintains a specific system pressure inside the hydronic loop. Most systems use "tap" water to maintain the system's water pressure, and almost always, that "tap" water contains minerals. A "tight" system (or a system that rarely loses water due to leaks) needs less consideration in terms of scale build-up, however, the issue of corrosion should still be addressed. If a system frequently adds water, scale buildup should be addressed.

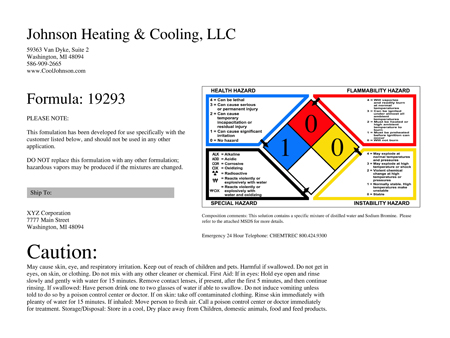

When designing a chemical treatment program for your hydronic system, dozens of factor come into play. Things like water pH and hardness, which vary from location to location need to be considered. If the water is too acidic, it may corrode the inside of the pipes, but if the water is too alkaline, mineral scaling may occur and reduce the efficiency of the system. Chemical interactions between the possible chemical choices, when developing a chemical treatment program, need to be considered. Mixing some chemicals can cause serious health and safety concerns, that should never be taken lightly, while mixing other chemicals may cause the beneficial properties of the the individual chemicals to negate each other.

Johnson Heating and Cooling is your best choice for providing your chemical treatment program, and here are some reasons why; we provide better services/products at lower prices. WE MAKE OUR TREATMENT PROGRAM CHEMICALS FROM SCRATCH. We buy many of our chemicals in the raw, 99% lab grade form and produce our chemical treatment programs from the ground up. We do not buy our chemicals from water treatment chemical providers, like much of our competition does, and then resell the program/ chemicals to our customers. Because we buy our chemicals at such low prices, we are able to pass the savings on to our customers. We have well over a decade of experience providing chemical treatment programs to customers. JHC owner, David Johnson, is highly educated in chemistry, he has taken many chemistry classes, has years of experience in the industry, has done extensive research on water treatment programs & strategies, has taken many classes on industry specific equipment needs, and has extensive knowledge of hydronic heat transfer systems. Johnson Heating and Cooling has a State of Michigan licensed professional engineer on staff and has a long and proud history of serving happy customers in the area of chemical treatment programs. Give us a call, and we would be happy to give you a free chemical treatment program quote.