JLA Medical BuildingBuilding Automation

In 2011 Johnson Heating and Cooling L.L.C. was contracted to install a new high efficiency low pressure heating boiler and a new building automation system that controls the building's pumps, swamp cooler, chemical treatment system, boiler, interior lights, and parking lot lights at JLA Medical Building, which is located in Waterford, Michigan.

BAS PageWhile beginning, the State of Michigan required, annual CSD-1 boiler inspections, maintenance, testing, and reports, the men from Johnson Heating and Cooling, LLC found that the old boiler had several problems that required costly repairs / corrections to be made due to safety concerns. Additionally, the old boiler was a cast iron sectional, natural draft boiler with an efficacity of about 72%, due to it's construction and efficiency loss because of sediment. After noting the incorrect configuration and problems with the old boiler, we ceased the CSD-1 report, testing, maintenance, and inspections and informed the owner that it would be profitable to replace the old boiler with a new high efficiency boiler, rather than to pay us to make the necessary repairs to a poor system. Johnson Heating and Cooling, LLC provided the building owner with a quote to replace the boiler and install a new building automation system, and our quote was accepted.

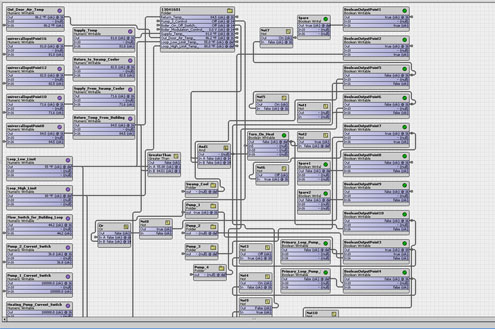

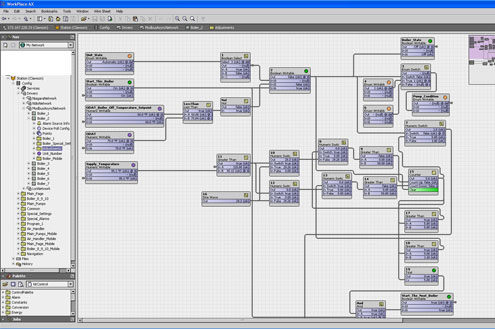

Johnson Heating and Cooling, LLC installed the new boiler within two days, and the building occupants were unaffected by the work performed by Johnson Heating and Cooling, LLC. The boiler was installed first, and after it's installation, the building automation system was installed. The main change out of the building automation system took place on an 18 hour work day, so that the heating and cooling system for the building would stay on-line, and no damage would come to the 40, or so, water cooled heat pumps that relied on the water loop for 70 degree water at all times. Before performing the controls change-out, we built the controls cabinet and programmed the server as needed to control the equipment after the new cabinet was installed. We did all of our work with out inconveniencing the operations in the building, and essential equipment was only taken off-line for a few minutes at a time.

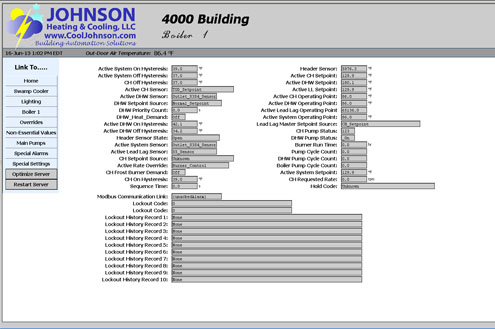

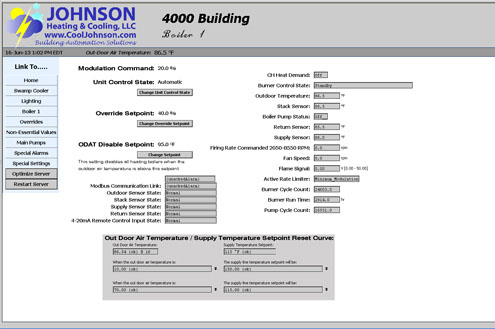

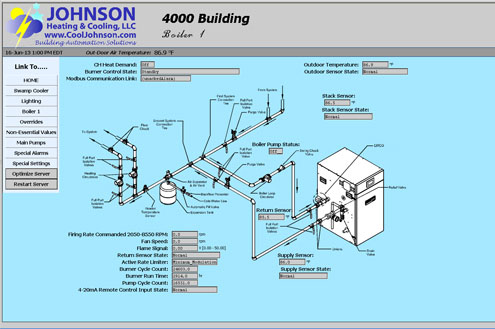

The building automation system at JLA utilizes a state of the art Mod bus registry interface with the Sage 2 controller in the Burnham Alpine Boiler. Johnson Heating and Cooling, LLC had written the Mod bus registry for the Burnham Alpine boiler's Sage 2 controller on a pervious project, and had dealt directly with the boiler manufacturer, Burnham, to obtain pertinent documentation from the manufacturer of the Sage 2 controller in the boiler. Weeks of data entry and programming yielded a level of equipment supervision rarely achieved by any controls company in the world. The level of supervision of the building automation system is so detailed that nearly every calculation and sensor reading that is made by the boiler's Sage 2 controller is reported to the building automation system. Because the boiler manufacture did not have, or even know what the documents that we requested were, it is simple logic to deduct that Johnson Heating and Cooling, LLC was the first company in the world to have integrated the Sage 2 controller into a building automation system in the way that we did. Flame signal readings, RPM of the inducer motor, and lock-out histories are only a few of the many boiler integration features in the JLA project.

Perhaps one of the most unique attributes of the building automation system is the level of alarming developed on a piece of equipment that is not commonly integrated into building automation systems. What is meant by this is that typically, a controls contractor will write an alarming code (if they do write alarming code, which many don't do much of) that will say something like: if the boiler has had a call for heat for three minutes and the discharge water temperature of the boiler has not risen by at least five degrees, "sound the alarm". With this project, as with many others that Johnson Heating and Cooling, LLC has done, we integrated directly with the controller in the boiler and used not only the style of alarm noted above, but also the many internal alarms located within the boiler's controller, which actually give the exact reason why a boiler has failed, such as "high head temperature-hard lock out failure", or "inducer motor failure". Often the end result is the same, the equipment requires service, however, service time can be greatly reduced because we already know what the cause of the failure is before we arrive on-site. Also, obtaining critical measurements like flame signal in voltage helps us to expedite the State of Michigan required, annual CSD-1 boiler reports, testing, maintenance, and paperwork, because we can obtain many values with the click of a mouse. We are not just in business to make money, we are also in business to save our customers money.

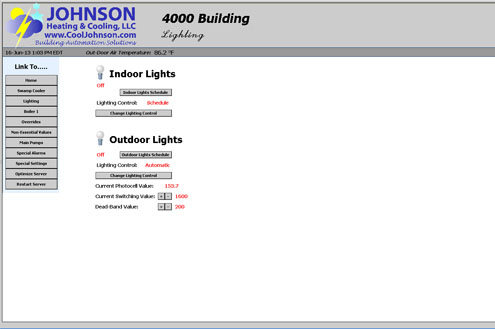

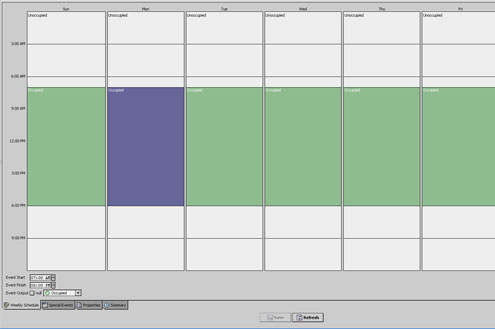

In addition to boiler control, supervision, and alarming, the building automation system also controls the interior and exterior lighting of the structure. Overrides were added to the building automation system interface so that the lighting system could be easily turned on or off for service. The parking lot lights, for instance are capable of operating based on a photo cell, a schedule, or can be manually turned off or on by the building automation system, which is accessible via any computer or smart device with access to the world wide web. The system is totally software manageable. The interior lighting is designed to function off of a schedule, but may also be set to on or off by with the building automation system.

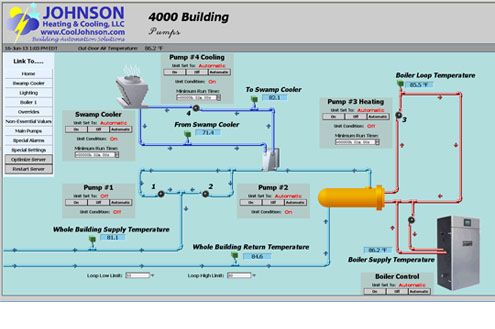

All 40 (or so) water cooled heat pumps operate by adding heat to, or taking heat from, a circuit of water that is pumped from the mechanical room to the ends of the building, and then back to the mechanical room. The water flows continuously through each of the water cooled heat pumps, and when a water cooled heat pump heats or cools, it simply adds or removes heat from the water. The Boiler adds heat to the water loop if the loop temperature becomes too low, and an evaporative cooling system is used to cool the loop temperature if it becomes too hot. The building automation system is responsible for determining what equipment to activate, when to activate the equipment, and when to deactivate the equipment. Small changes in the operating program can have huge impacts on the efficiency of the total system.

The building automation system also features cooling water chemical treatment supervision and control. Cooling water chemical treatment is a profession in and of itself, and there is a lot of chemistry and mathematics involved in determining the proper mixtures when formulating a chemical treatment program for a customer. Integrating the chemical treatment system into the building automation system is always the best way to administer a chemical treatment program because of several reasons. Firstly, managing a chemical treatment program via a server based building automation system is very accessible. Changes made to the program can be done across town, or even across the country. Secondly, because most water treatment programs simply rely on timers and sometimes water meters to administer chemicals to cooling water, there is often waste. Administering chemicals based on readings and calculations (like equipment run time, conductivity, etc.), as can be done with a properly written chemical treatment program in a server, offers the chemical treatment program administrator much more flexibility in cutting costs and saving chemicals. Thirdly, calculated chemical level alarms may be integrated into the system so that e-mails are sent out just prior to chemical levels reaching zero. Fourthly, the treatment of the system can be geared back when the system is used less. Legoinarre's disease is the primary reason why chemical treatment programs must be used with evaporative cooling systems. If the water is not being aerated or circulated through the system, like in the winter, the cooling water treatment may be geared back a bit. The fifth and last reason why cooling water chemical treatment programs are best administered via a building automation system is because there are no limitations on developing a good control program with a server, while without a server the chemical treatment engineer's ability to design a control program is restricted to within the operational functionality of the hardware that he is using.